정창 링 다이

홈 > Mechanical spare parts > 링 다이 > 정창 링 다이

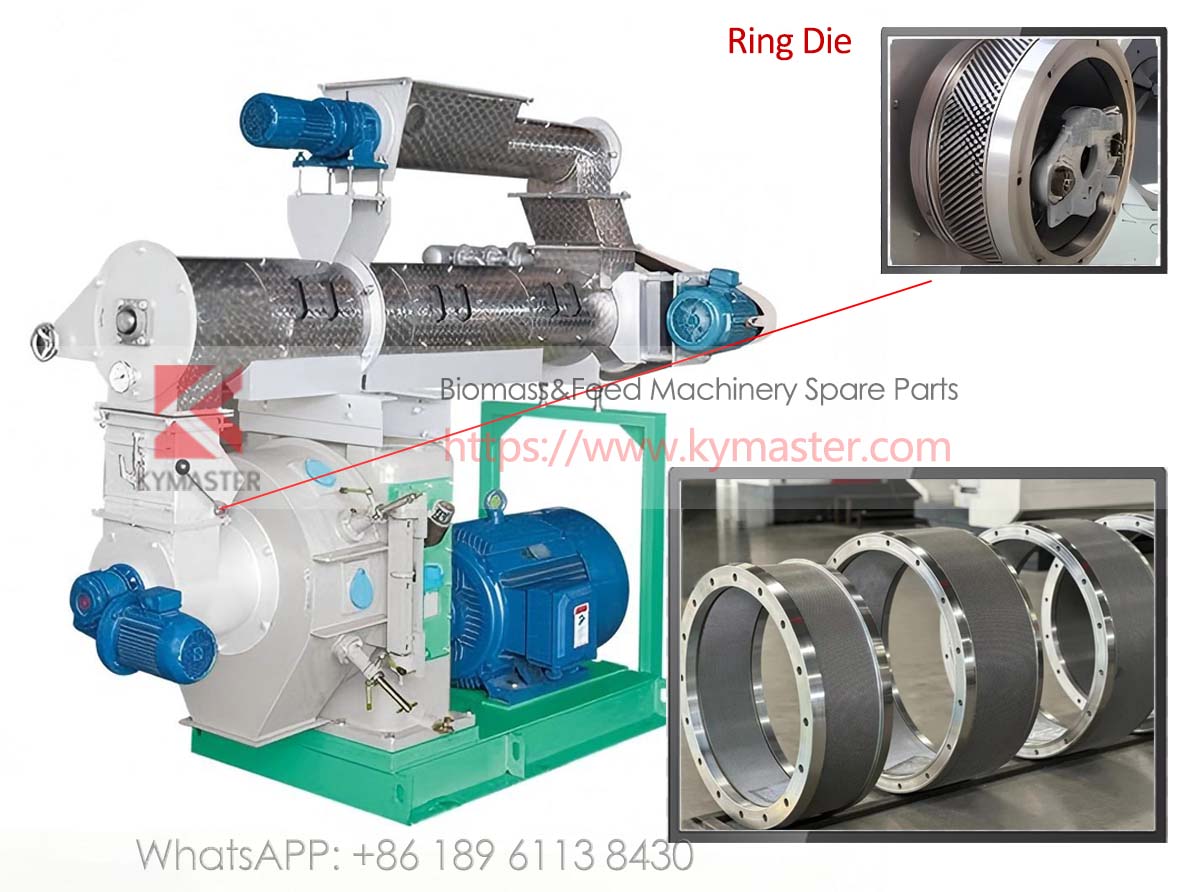

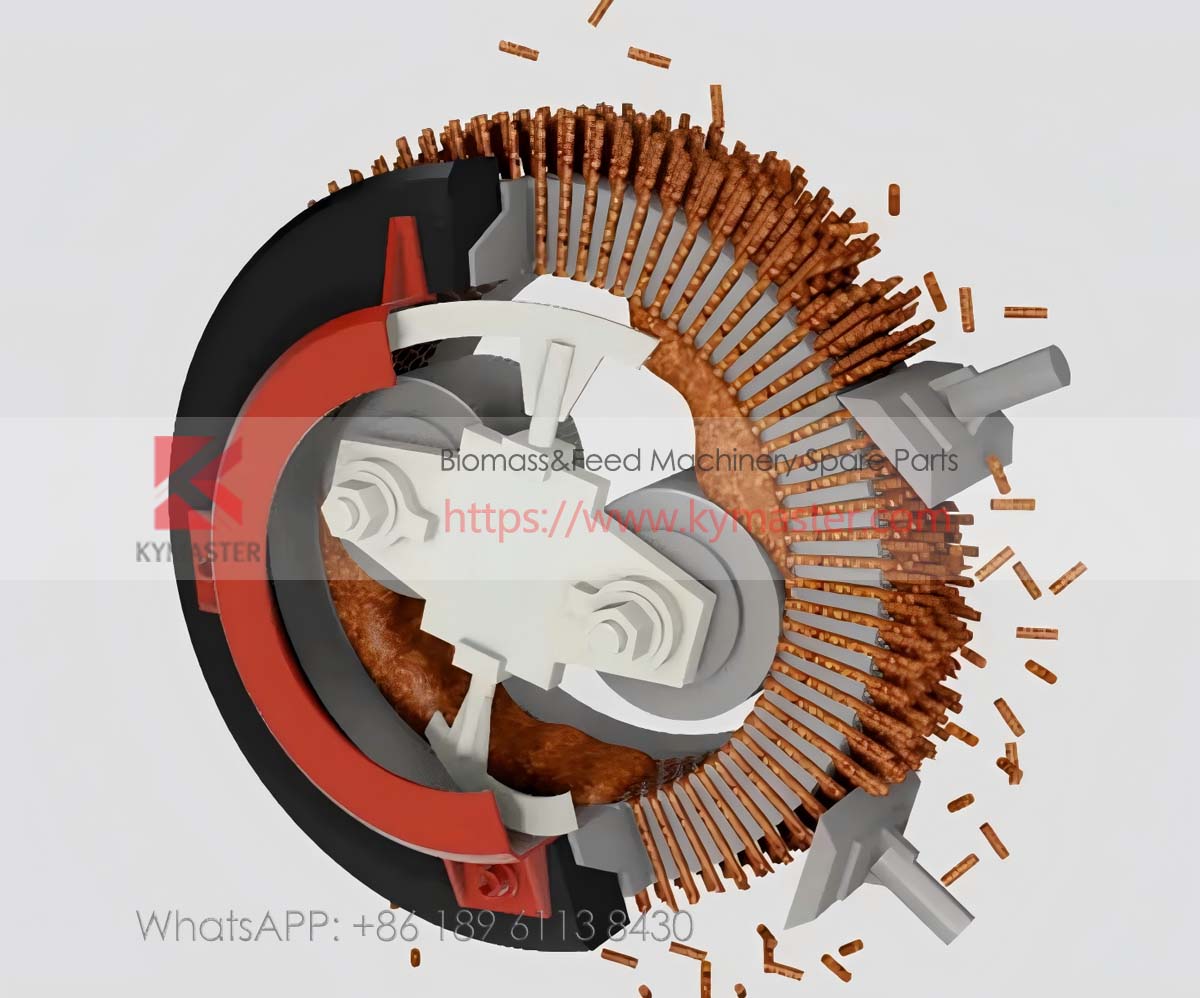

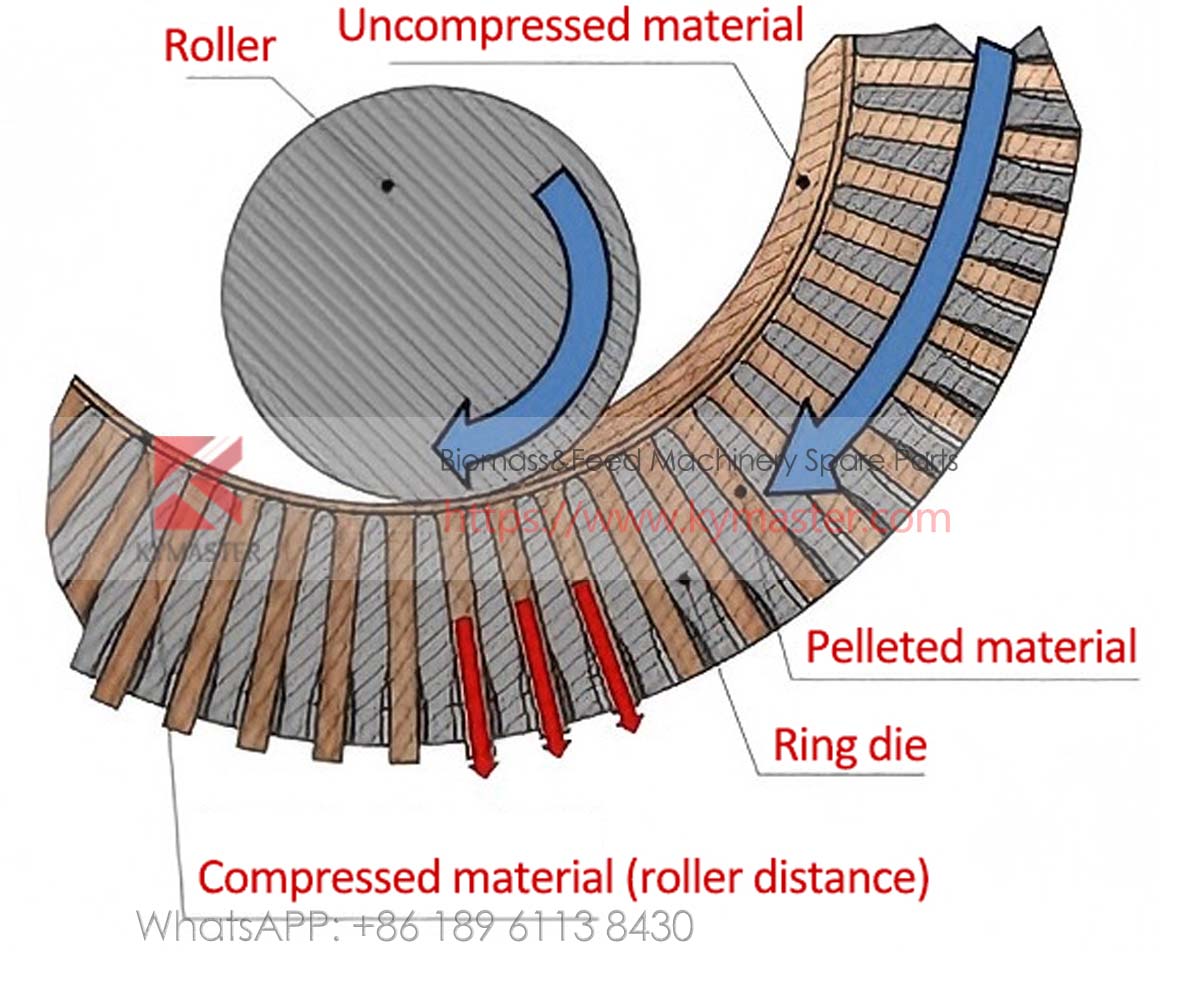

Ring die is one of the key parts of a pellet mill, which is wearing part and expensive. Its quality and durability determine the service life, production capacity and pellet quality, furthermore, directly affecting production costs.

The main failure of the ring die is due to worn-out die holes and inner surfaces (rendering it unusable), though cracking and clogging (preventing pellet extrusion) also occur in some cases.While the die's lifespan is largely determined by its material and manufacturing process. Additionally, for the same material and processing method, its life time is also influenced by factors such as raw material properties, processing parameters, and operational techniques.

Moreover, the smoothness of the die hole surface directly affects whether the ring die can discharge material properly during the initial trial pressing.

Our company supply dies with a ID up to 900mm, OD up to 1,440mm,hole diameters from 1.0mm to 30mm, compression rate is up to 25. We manufacture about 5000pcs dies every year and customized pellet ring dies for different brands of pellet mill, learn more about our ring dies processing

1. 설명 of Zhengchang Ring Die

매끄러운 다이 구멍, 멋진 외관, 대용량, 고품질, 긴 수명

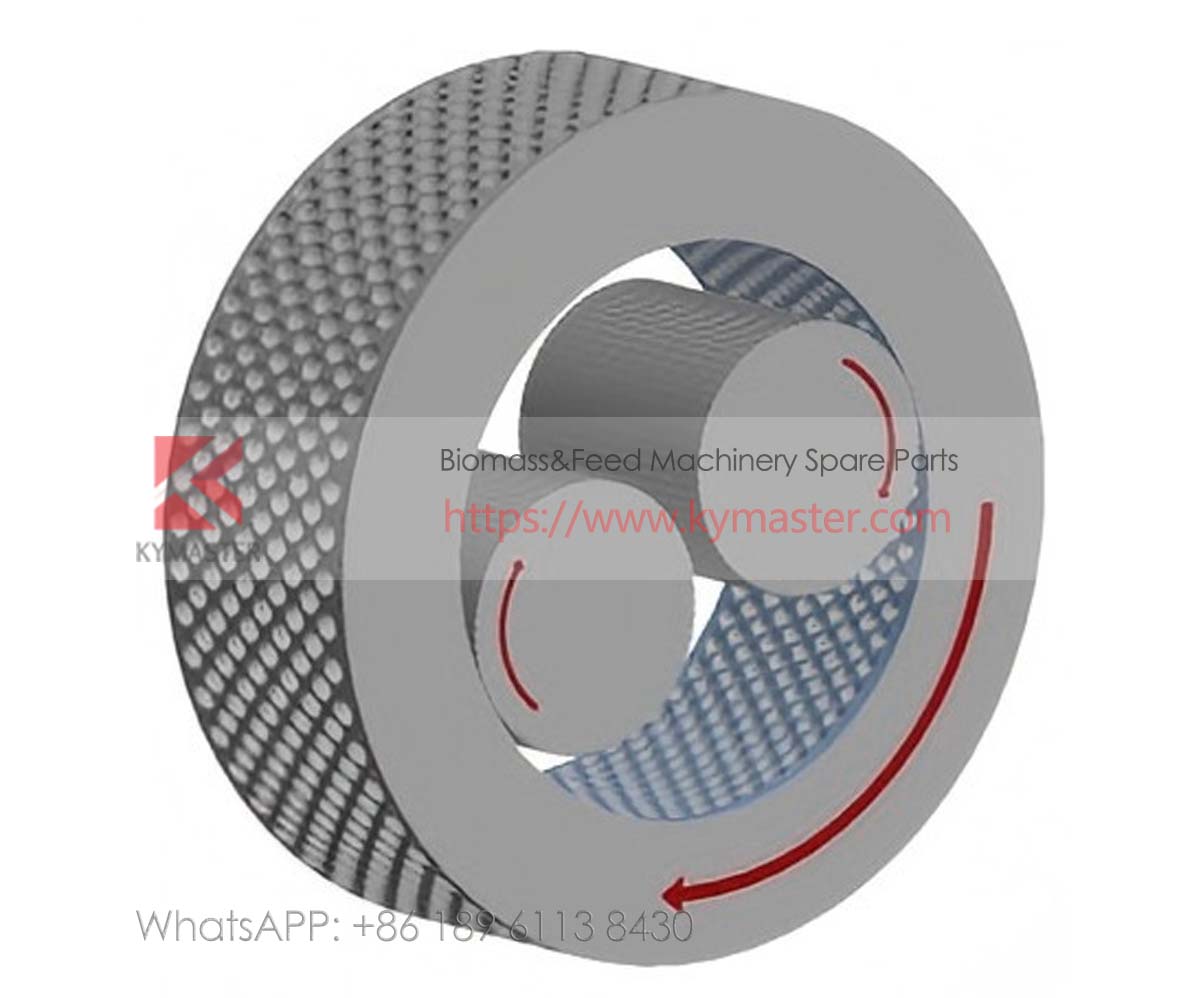

1.1 완전 자동 CNC 링 다이 드릴링 머신은 매끄러운 마감, 좋은 피드 전망, 고용량으로 한 번 모양의 다이 구멍을 보장합니다.

1.2 펠릿 밀링 금형의 작업 수명 향상을 위한 진공 열처리 기술.

1.3 고객의 필요에 따라 압축률과 강도를 설계할 수 있습니다.

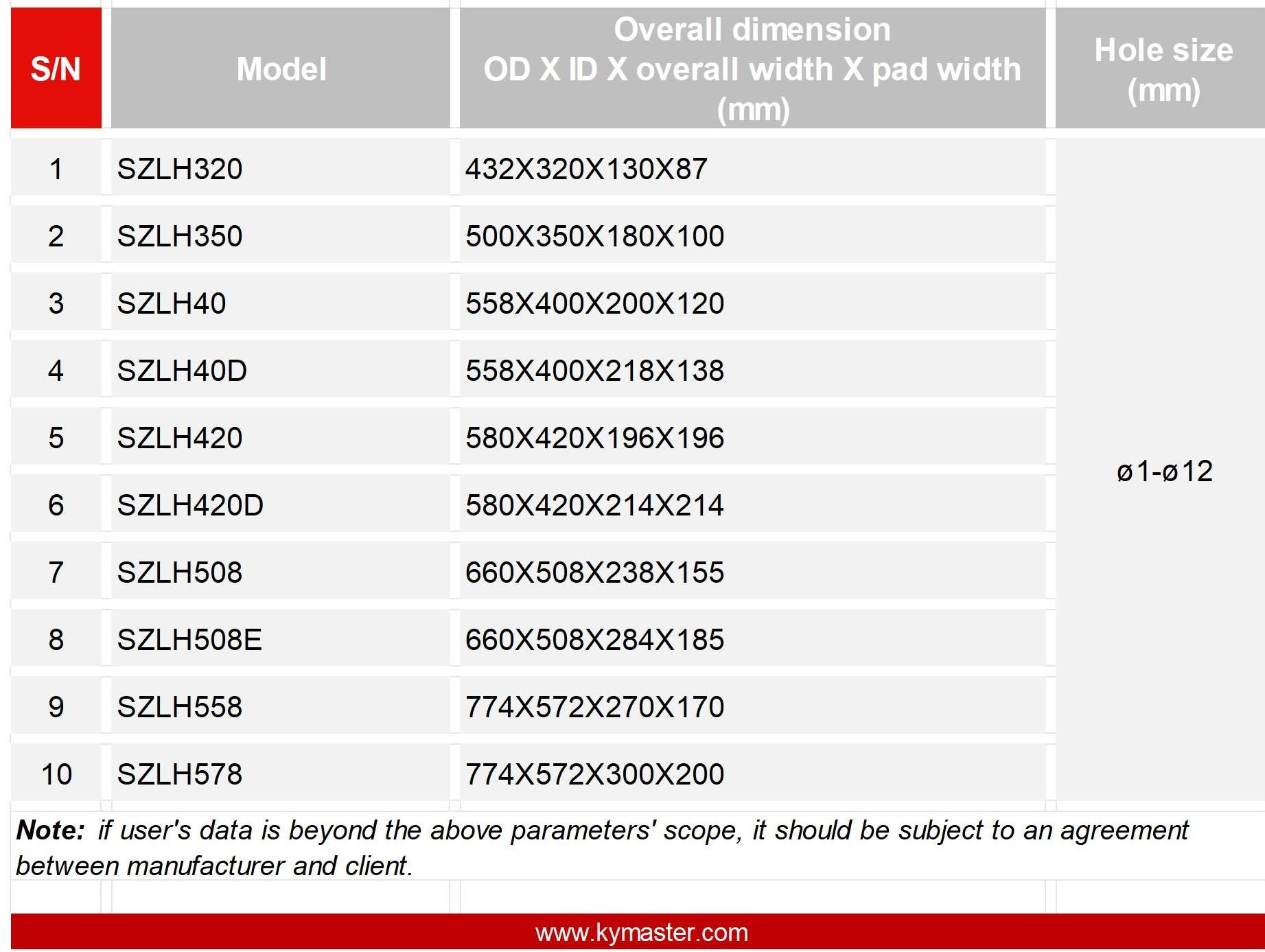

2. Zhengchang ring die's technical parameters

Superior Wear Resistance, Smoother Operation – Upgrade to Our Ring Dies Today!