Roller assembly

Home > Mechanical spare parts > Products > Roller assembly

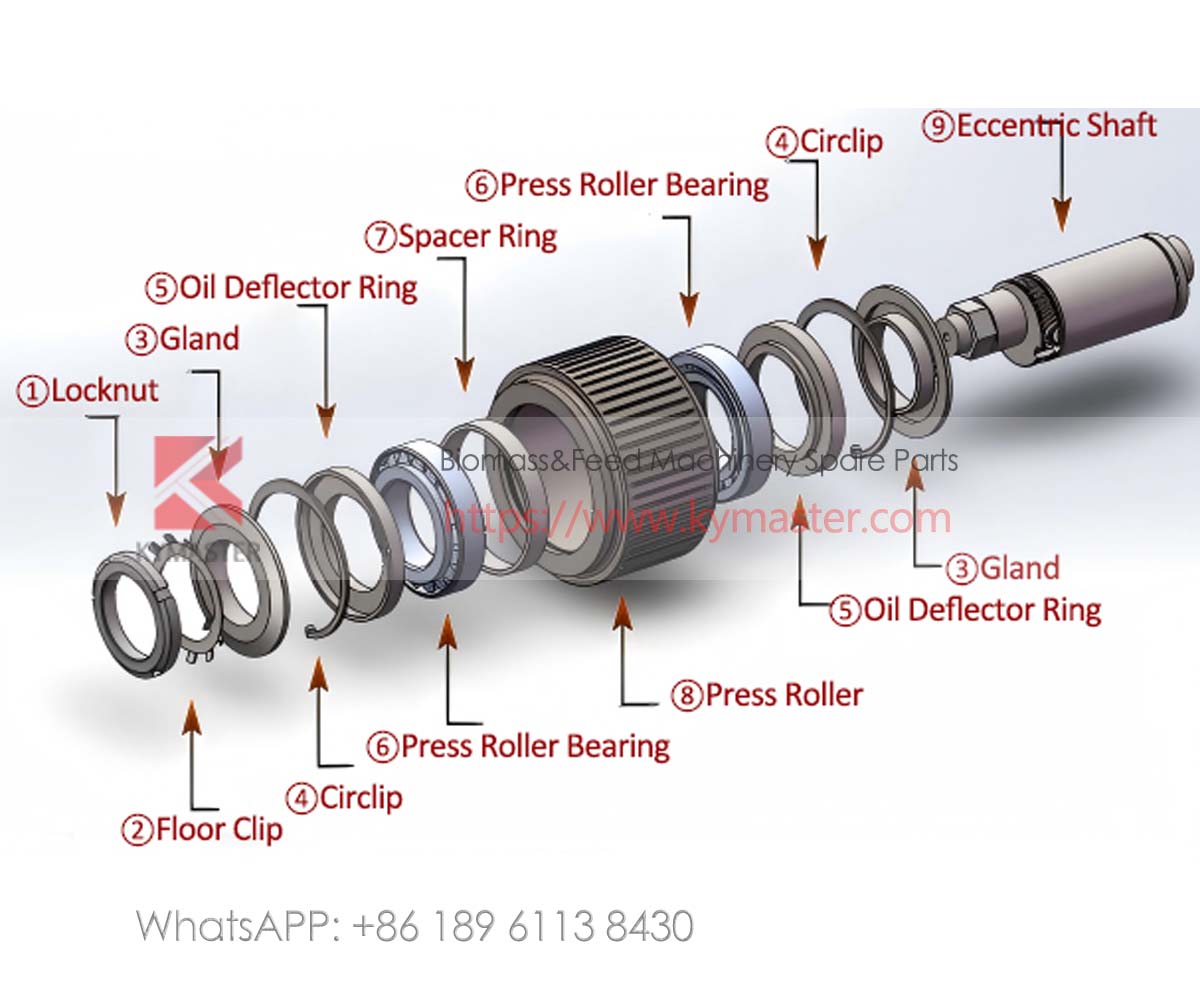

Pellet mill roller assembly is a critical component in a pellet mill, compressing raw materials into pellets through the counter-rotation of two rollers.

Typically composed of press roller, bearings, eccentric shaft, glands, circlips, floor clip, oil deflector rings, spacer ring and locknut, this assembly ensures uniform and efficient compression of materials into desired granular forms.

1.Assembly Steps

1.1 Component Machining: Laser alignment of shaft and roller bores (tolerance ±0.01mm).

1.2 Heat Treatment: Vacuum quenching to eliminate internal stresses.

1.3 Dynamic Balancing: Tested at 1,500 RPM to minimize vibration.

1.4 Sealing Integration: Multi-labyrinth seals + Viton® gaskets for dust/waterproofing (IP66).

1.5 Final Testing:

Load test: 200% of rated load for 24 hours.

Thermal imaging to verify heat dissipation.

2. Key Advantages

2.1 Durability & Performance

50% longer lifespan vs. conventional assemblies due to:

Isotropic superfinishing reducing friction losses by 35%.

Modular design enabling individual part replacement.

Load Capacity: Supports ≥10 tons/cm² pressure on the die.

2.2 Maintenance Efficiency

Quick-release mechanisms: Roller replacement in <30 minutes without disassembling the shaft.

Centralized lubrication ports for automated grease injection.

2.3 Energy Savings

Optimized roller geometry reduces motor power consumption by 15-20%.

Ceramic hybrid bearings (optional) cut energy loss by 25%.

2.4 Customization

Adjustable gap settings (0.1–0.5mm) for diverse feedstock (e.g., wood, feed, biomass).

Explosion-proof versions for flammable dust environments (ATEX certified).

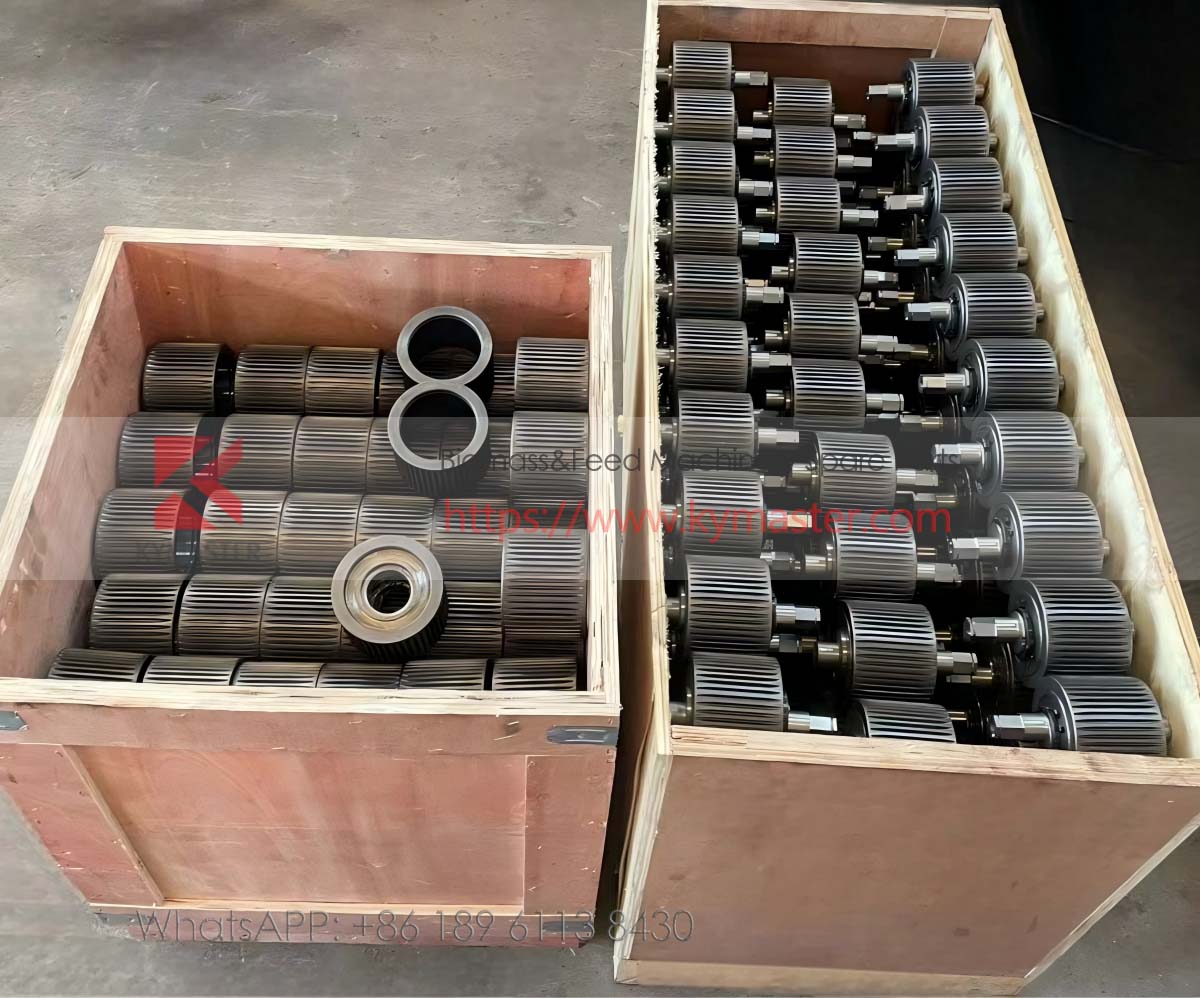

Pellet machine roller assembly package

Our pellet machine roller assembly combines German-engineered precision with Japanese-grade bearings, ensuring ≤0.001mm runout tolerance. Field data shows 99.3% uptime in 24/7 pellet production lines. Contact us now! Email: kymaster@yeah.net